| 3/16" | 1/4" | 5/16" | 3/8" | 1/2" | 5/8" |

|---|---|---|---|---|---|

| 4.8mm | 6.3mm | 7.9mm | 9.5mm | 12.7mm | 15.9mm |

| 3/4" | 1" | 1 1/4" | 1 1/2" | 1 5/8" | 1 3/4" |

| 19mm | 25.4mm | 31.8mm | 38.1mm | 41.3mm | 44.5mm |

| 2" | 2 1/4" | 2 1/2" | 2 3/4" | 3" | |

| 50.8mm | 57.2mm | 63.5mm | 69.9mm | 76.2mm | |

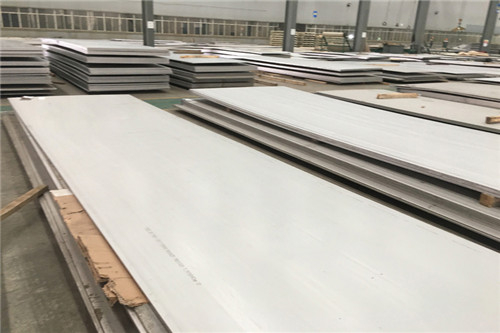

Alloy 2507 (UNS S32750) is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity, and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

General Properties

Alloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

The impact strength is also high. Alloy 2507 is not recommended for applications which require long exposures to temperatures above 570°F because of the risk of a reduction in toughness.

Applications

Oil and gas industry equipment

Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

Chemical process industries, heat exchangers, vessels, and piping

Desalination plants, high pressure RO-plant and seawater piping

Mechanical and structural components, high strength, corrosion-resistant parts

Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

Standards

ASTM/ASME .......... A240 - UNS S32750

EURONORM............ 1.4410 - X2 Cr Ni MoN 25.7.4

AFNOR.................... Z3 CN 25.06 Az

Corrosion Resistance

General Corrosion

The high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid. 2507 also provides excellent resistance to inorganic acids, especially those containing chlorides.

In dilute sulfuric acid contaminated with chloride ions, 2507 has better corrosion resistance than 904L, which is a highly alloyed austenitic steel grade specially designed to resist pure sulfuric acid.

Stainless steel of type 316L (2.5%Mo) cannot be used in hydrochloric acid due to the risk of localized and uniform corrosion. However, 2507 can be used in dilute hydrochloric acid. Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.